Ñ å ê ö è ÿ 1 ÐÀÑÏÐÎÑÒÐÀÍÅÍÈÅ ÒÐÈÇ Â ÌÈÐÅ

THE ROLE OF PRACTICE IN MASTERING TRIZ

Iouri Belski, M.Sc. and PhD (Physics), SMIEEE, founder of TRIZ4U, Australia

Abstract: The paper compares the outcomes of TRIZ training programs conducted by TRIZ4U in Australia, Singapore and Malaysia over the last 5 years. Some training programs were run as three- to five-day face-to-face workshops and did not have any practical follow-up. Other training programs incorporated both face-to-face component of a similar duration and comparable theoretical content as well as practical project work conducted by the participants after the face-to-face component. It has been found that the latter training programs resulted in much higher rate of participants using TRIZ tools 6 months after training.

Introduction

The amount of information created in fields of science and engineering annually, already exceeds what an ordinary engineer is able to comprehend. And the rate at which new information is created is rapidly growing. In his profession, an engineer is expected to create new products and to resolve problems related to existing products. Usually, only a limited period of time is given to an individual and/or team to achieve this. A lack of formal education in engineering problem-solving means that trial and error is the most widely used approach in day-to-day engineering work. It is also common for an engineer to use brainstorming and deploy various analogies when faced with a problematic situation1. These approaches to problem-solving are not systematic. The thoughts and actions of an engineer using trial and error are unstructured, so the result of the problem-solving process is unpredictable and is heavily dependant on the personality of a problem solver and her/his experience.

Life expectancy of products and processes in the 20th Century was sufficient to permit a number of redevelopments and 'improvements' to the products and processes over their lifespan. Engineers using trial and error were able to cope with the existing pace of product development and product improvement. The natural life of products today is much shorter. This is understood even by the world's tax offices. Most of them allow businesses to replace laptop computers every two to three years, for example. The engineering profession of the 21st century requires solutions of a different sort. In the words of Charles Handy, "Life seems to be a succession of open-ended problems with no right answers, but problems, nevertheless, which demand an answer." 2 Therefore, engineering education needs to be adjusted to ensure that engineers of the next decade will be able to deal efficiently with open-ended problems, which often occur under uncertainty and with considerable information overload. To achieve this, engineers need to be more creative - they must become more systematic in their problem-solving work.

Over the years, many authors have investigated the skills of problem-solving and creativity3-5. They have suggested that in order to be able to approach open-ended problems, a practitioner needs to improve his/her thinking skills. Moreover, they found that those thinking skills can be taught 4, 5. Scholars model thinking processes by emphasising various aspects of cognition. They have subdivided thinking into many areas: systematic thinking, systems thinking, critical thinking, lateral thinking, wishful thinking, big-picture thinking etc.6-8 Researchers have also propose various tools to improve human thinking.1, 4, 5 Thinking in general is defined as using the mind "to consider something, to form connected ideas, to try to solve problems…".9 Therefore, an improvement in thinking may be related to any aspect of cognition.

There are many courses on creativity which are advertised as enhancing thinking skills. TRIZ thinking tools are specifically promoted as boosting thinking skills of engineers, and therefore changing the outcomes of their engineering work. We tried to find out whether this is true and whether the outcomes of traditional TRIZ workshops which are conducted over a few days and do not have any follow-up are the same as the outcomes of programs which also incorporate project work.

Method

Over the last 5 years TRIZ4U conducted tens of TRIZ training programs. Hundreds of engineers, scientists, managers and school teachers were involved. All these training programs can be divided into two categories:

Three- to five-day TRIZ workshops which have not been followed by any compulsory practical work.

Three- to seven-day TRIZ workshops which have been followed by compulsory individual project work.

Participants of training programs of category A studied the following tools of TRIZ: Situation Analysis, Method of the Ideal Result, Substance-Field Analysis, 40 Innovative Principles and the Contradiction Table.

Participants of training programs of category B learnt the same tools of TRIZ as the participants of training workshops of category A plus they were introduced to TRIZ Laws of Development of Technical Systems. Workshops of category B were followed by a practical component, whereby engineers were involved in individual projects closely related to their work. Engineers involved in training programs of category B continued to work full time and were able to use up to 5 hours a week for their TRIZ project work. Most of the individual projects were unresolved company problems. Some projects were devoted to new product development, cost reduction and failure analysis and prevention. In their project work, engineers were requested to follow the Seven Steps of Systematic Thinking.10 TRIZ4U provided project coaching for every project.

Both short-term and long-term evaluations of the impact of TRIZ4U programs were conducted. To evaluate the short-term outcome, the participants were asked to fill in a feedback form on the last day of the face-to-face workshop. Long term evaluation was conducted in two ways. The participants of training programs of category A were contacted by e-mail and by telephone 6 months after workshops. The participants of training programs of category B provided TRIZ4U with their reflections directly after they finished the practical component of the training program. They also had been contacted 6 months later for further reflections.

Thinking Tools of TRIZ

TRIZ is the Russian acronym for Theory of Inventive Problem Solving. It is a well-established system of tools for problem-solving, idea generation, failure analysis and prevention. TRIZ originated in Russia more than 50 years ago.5 TRIZ thinking tools branch from the evolution of products and processes, which have been revealed through the analysis of thousands of patents. Developed behind the iron curtain, TRIZ was used by Russian engineers and contributed to many inventions. TRIZ entered the Western world in the early 1990s, and has already helped many western companies to achieve enormous improvements. The following is a short description of the tools which the participants of the training were taught.

Situation Analysis (SA)

SA is designed to question the assumptions of a user and his/her perception of the problem. To solve a problem, it is imperative to understand what the problem is about. Our perception of the situation and our entire outlook concerning its improvement often changes when various needs of the situation become apparent.

When humans consider real problems (situations) they often mix many issues together. Technical matters are often blended together with human emotions. These issues are indeed related, but they often correspond to very different aspects of the situation and can therefore be dealt with differently. Usually, the people improving the situation attempt to address all the human and technical issues at once. This is not the most efficient method by which to achieve success. Proposed actions rarely achieve the outcomes expected. An approach such as this often results in time and resources being wasted.

The SA tool requires a user to answer a set of questions. This is intended to achieve the following outcomes:

· to clarify the situation under consideration

· to separate human perceptions from the reality of the situation

· to identify different problems embedded in the situation

· to formulate the tasks that were to be undertaken for the situation improvement

Method of The Ideal Result (MIR)

Method of the Ideal Result (MIR) has been developed by the author.11 MIR is based on the TRIZ notion of the Ideal Ultimate Result (IUR).

We often find ourselves in situations where improvement is necessary, but the element that should be focussed upon is not always apparent. Identifying the correct element to focus on is vital. Unless an engineer applies his/her skill and invests money into upgrading the system part which holds up overall performance the most, the outcome of such improvements is likely to be quite unsatisfactory. The first part of MIR is designed to aid users in pinpointing the very element upon which to focus.

Another common mistake made by many engineers is related to the introduction of additional resources (e.g. parts, elements, substances, etc.) to improve the situation, without having a clear picture of what resources are originally available. Any new resource costs money. Most existing resources are either free or inexpensive. Moreover, the existing resources are already available and do not need to be supplied! The second part of the MIR procedure helps a user to identify the resources available, and consider how these resources may be used in improving the situation. All participants learnt how to employ the TRIZ4U MIR Proforma.12.

Overall, MIR helps a user to accomplish the following:

· to identify the direction towards an effective and simple solution

· to separate different areas of improvement, and to identify the elements one needs to focus on to deliver the most efficient improvement

· to recognize all the resources at hand

· to sift through all the available resources, with the aim of seeing whether they may help in improvement

Substance - Field (Su-Field) Analysis

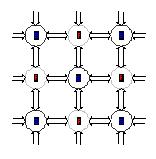

Substance-Field Analysis pictures any natural and man-made system as a set of interacting elements - a set of substances interacting with each other by means of fields, which are generated by the substances. Substances and fields in Substance-Field Analysis are not equal in representing systems - substances describe real system elements and fields show the interactions between these elements. Nonetheless, both substances and fields are represented in a similar manner - by circles. This ensures that vastly different real systems are modelled in a similar way - by means of circle-substances and circle-fields. Such generalisations enable a practitioner to represent complex systems by simple structures of circles. This allows a user to consider different systems in a uniform way and to apply similar rules to resolve dissimilar problems. An example of a two-dimensional representation of a system, as a set of fields and substances, is shown in Figure 1. The circles with the letter S represent substances, the circles assigned with F symbolise the fields generated by these substances.

Figure 1. A two-dimensional representation of a system in Su-Field

The real picture of a system is often more complicated and has more dimensions than the one shown. Nonetheless, such models and generalisations of circle-substances and circle-fields help to systematise our thinking.

Su-Field Analysis is a general tool for idea generation and failure analysis and prevention. It models a system through a set of interconnecting substances and fields. This converts the real task into its Su-Field model and helps to clearly identify the conflict zones of the system. These conflict zones are broken down into conflict triads. Five model solutions are considered for every conflict triad. Eight fields of MATCEMIB (Mechanical, Acoustic, Thermal, Chemical, Electric, Magnetic, Intermolecular, Biological) are deployed to "translate" model solutions into real solutions. All participants of TRIZ4U workshops studied contemporary Su-Field Analysis13.

The Contradiction Table (CT) and 40 Innovative Principles.

The 40 Innovative Principles are "solution recipes", that have been successfully used in thousands of patents. To derive the 40 Innovative Principles, more than 20,000 patents were analysed.5 It was found that dissimilar tasks from distinct areas of engineering and science were often solved in a similar manner. The 40 Innovative Principles group these ideas into larger groups, called principles. The 40 Principles can be used separately, but they yield better solutions when used together with the Contradiction Table. The Russian versions of the TRIZ Contradiction Table (CT) and 40 Innovative Principles have remained unmodified for over 25 years.

The Contradiction Table (CT) and 40 Innovative Principles, when used together, represent another idea generation tool which models real systems. Unlike Su-Field, which provides the user with a wide variety of general ideas for implementation, these tools offer solution ideas which are design-ready. The TRIZ4U CT Proforma was learnt by all the participants to model systems accurately.12.

Laws of Development (LD) and Patterns of Evolution (PE) of Technical Systems

The Laws of Development of Technical Systems are an efficient tool for product strategy. Laws of Development provide the general directions of systems' evolution. They provide insight into the directions of technology/product/concept evolution, and help in designing tomorrow's products today, and in making the right decisions with regard to disruptive innovations. Patterns of Evolution of Technical Systems (PE) cover the reasons for the evolution of products, reveal patterns of product evolution and provide further insight for designing tomorrow's products today. PE is often studied together with the Laws of Development. Only some participants of category B used the Laws of Development and Patterns of Evolution of Technical Systems in their project work.

Seven Steps of Systematic Thinking

Engineers involved in training programs of Category B were asked to conduct their practical work using the Seven Steps of Systematic Thinking10:

1. Situation analysis.

2. Revealing the system's stage of development.

3. Identifying the ideal solution.

4. Idea generation.

5. Failure prevention.

6. Adjusting the super-system and sub-systems in accordance with the solution found.

7. Reflection on the solution and the process of the solution.

Results

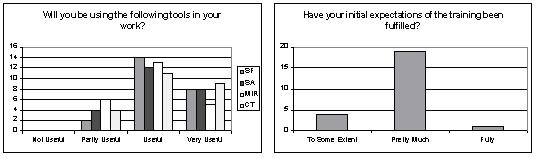

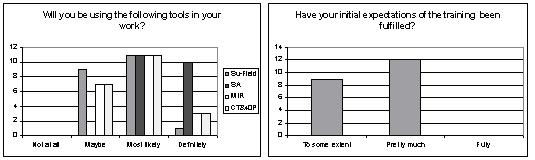

In accordance to the participants' feedback they attended the training in order to learn new problem-solving tools and to enhance their ability to resolve their day-to-day work problems. Two aspects of their feedback immediately after the face-to-face workshops are presented in Figures 2 and 3.

Figure 2. Usual feedback after face-to-face TRIZ4U training program of Category A

Figure 3. Usual feedback after face-to-face TRIZ4U training program of Category B

It seems that the participants expecting to use TRIZ after training evaluated the tools learnt with higher scepticism then the participants who did not expect to be forced to use the tools. Overall immediate feedback of the participants of training programs of both categories depicted in Figures 2 and 3 indicates more or less equal likelihood of usage of the TRIZ tools learnt by both categories.

Nonetheless the long-term outcomes of the training programs were vastly different. Less than 10% of the participants of training programs of Category A were using TRIZ 6 months after workshops. Most of them appeared to be preoccupied with other activities and said to be unable to find a good problem to trial TRIZ. Moreover, the users in the 10% group were unlikely to deploy more than two tools of TRIZ. On the contrary, more than 70% of the participants of training programs of Category B were using TRIZ 6 months after they finished their project work. Most of them were exploiting at least three tools and some participants have even introduced the tools to their colleagues.

The following are reflections of some participants involved in TRIZ4U programs of Category B.

"TRIZ has provided a systematic analytical approach to problem solving and idea generation in design as in the case of this project. It has provided some great ideas which were never thought of while designing the conventional way."

"The ideas generation phase is an enriching experience while using TRIZ tools. There is always a tendency for designers to focus on an initial idea to solving a problem and overlooking other methods that may be more appropriate. TRIZ encourages the designers to look beyond the fields other than the one he is most familiar. It is very natural for a mechanical engineer to solve a problem using mechanical means, while an electronic engineer would solve the same problem by electronic means."

"On the whole, TRIZ tools offer a systematic thinking process which effectively reduces the traditional thinking process like brain storming, fish bone diagram, etc. It assists the designer by recording the thinking process, which eventually leads to the solution. In this way, the points discussed during the thinking process will not repeat itself."

"One important lesson I learned using TRIZ was: "even if we find a good idea, seemingly the best solution, during any intermediate process of problem solving, we should not stick to it and we should not think it the unique, best solution. We should better treat our thinking process more objectively and apply the problem solving steps of TRIZ properly to our own problem solving; thus we should be able to make our own mind more relaxed to generate a variety of solution concepts."

"After much practices of using the TRIZ tools, it has slowly set into my thinking habit. For example, when I need to purchase something, I will subconsciously ask myself what is the "super-system" of the "system" I am buying and can I fulfil the "super-system" with something else? I did not notice that I was doing it, until I have done it."

"TRIZ brought out the structure of ideas and thought in various stages to solve my project. Although the solution was pretty much similar to the current solution, but the time required deriving the solution was shorter (i.e. 2 months instead of 12 months). The cost of trial and error was eliminated therefore reducing the developmental cost. Should this project have started with TRIZ, cost, man-hours and development lead-time could have been significantly reduced."

"Through the application of the various TRIZ tools, it has help in generating the various possible solutions which was previously not thought of."

"TRIZ in a way, helped me to thoroughly search and find the root problem before ideas of possible solutions via the various field available in the world are found." (Project on failure analysis).

"TRIZ has also structured the approach in my thinking process. It has opened a new era of areas in my research to be explored. This structure has allowed to analyse on what have I not covered or duplicated in my research." (R&D project).

"TRIZ helps me in the project because it is a systematic way of creating new ideas or problem solving. By following the steps it triggers new ideas naturally. Without a system it is much more difficult to develop new idea."

"The TRIZ methodology has brought about a systematic approach to problem solving. The same set of tools used at different stage leads into a detail and in-depth thinking, which at most times was not given much attention."

"Basically, I feel that TRIZ on the overall helps me to cover thoroughly the different aspects of the problem in hand. The systematic approach to the problem helps me to focus and understand the problem better. It is a much better tool than the normal brain-storming session that we have."

"The process of finding the solution in TRIZ is very structured. This helps me a lot. For me, I am always quick to propose a 'best' solution and this will actually stifle the generation of other better solutions. TRIZ actually takes away this bad habit. It breaks a complex problem down into many digestible subtasks. This is beneficial especially it is a complex system."

Overall, the reflections of the engineers can be categorised into four major perspectives:

· They identified that there was a lack of systematic problem-solving tools in their engineering work, prior to the introduction of TRIZ thinking tools.

· Engineers clearly expressed that the TRIZ thinking tools had helped them to come to solutions they were unable to reach before, and often in much less time than was anticipated.

· They found that their own thinking was affected by the experience - it became more systematic.

· The participants were able to utilise their existing knowledge more effectively.

Conclusion

Although a short-term feedback of participants of all TRIZ4U training programs identified an interest and intent of most of the participants to use TRIZ tools in their day-to-day work, only the participants of training programs which incorporated individual project work were likely to use the tools regularly 6 months after training. Therefore, practice is not only essential in mastering TRIZ. It is also vital in retaining its regular usage at a workplace.

Bibliography

1. King. B., Schlicksupp, H., (1998), The Idea Edge: Transforming Creative Thoughts into Organizational Excellence, GOAL/QPC, Methuen.

2. Handy, C., (1997), Finding sense in uncertainty, in Rethinking The Future, edited by Rowan Gibson, Nicholas Brealey Publishing, London.

3. Kivenson, G., (1977), The Art and Science of Inventing, Van Nostrand Reinhold Company, NY.

4. Thring, M.W., Laithwaite, E. R., (1977), How To Invent, The Macmillan Press Ltd, London.

5. Altshuller, G.S., (1984), Creativity As An Exact Science, Gordon & Breach Science Publishing House, New York.

6. Senge, P. M., (1990), The Fifth Discipline: The Art And Practice Of The Learning Organization, Doubleday, New York.

7. Langrehr, J., (1994), Become a better thinker, Wrightbooks Pty Ltd, Melbourne.

8. de Bono, E., (1990), Lateral Thinking, Penguin Books, London.

9. Hornby, A. S., (2003) Oxford Advanced Learners Dictionary Of Current English, Oxford University Press.

10. Belski I., (2002), "Seven Steps to Systems Thinking", Proceedings of the 13th Annual Conference and Convention, Australian Association of Engineering Educators, Canberra, Australia, Sept., pp.33-39.

11. Belski, I., (1998), I Wish The Work To Be Completed By Itself, Without My Involvement: The Method Of The Ideal Result In Engineering Problem Solving, Proceedings of World of Innovation and Strategy Conference, Sydney, pp194-199.

12. Belski, I., (2005), A Course On TRIZ (Su-Field Analysis, Situation Analysis, Method of the Ideal Result and the Contradiction Table), TRIZ4U, Melbourne.

13. Belski, I., (2005), Improve Your Thinking: Substance-Field Analysis, TRIZ4U, Melbourne.

Âîçâðàò ê Äîêëàäû íà êîíôåðåíöèè "MATRIZ Fest 2005"

|