|

|

|||||||||

By Val Kraev

Editor's note: Kraev's Korner was first published in the newsletter of the Altshuller Institute in 2005. Our thanks to the Altshuller Institute and the Technical Innovation Center for letting us reprint this educational series. Previous lessons can be found by searching the TRIZ Journal's archives.

ARIZ is the acronym for the Russian name "algorithm for solving the inventor's problem" and it is one of the analytical tools of TRIZ, uniting a variety of other TRIZ tools. The main goal of ARIZ is to logically transform the initial problem situation into solution concepts for that problem. It is a step-by-step modeling procedure of directed development for solving a problem.

ARIZ has been modified since 1956 when more than 10 different versions of the algorithm are known. The last generally recognized modification is ARIZ-85B. This modification contains operators for the analysis and solving of difficult technical problems that could not be solved with the application of any other TRIZ tools individually: principles, s-field analysis and standards.

ARIZ-85B contains nine parts (which include 40 step-by-step procedures for problem resolution):

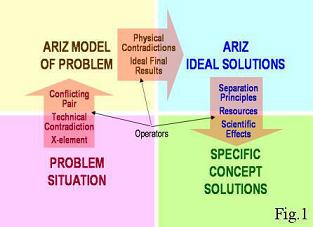

Generally, the process contains certain basic consolidated fragments. First, an initial customer problem situation is transformed into the problem model with help of operators: a technical contradiction between two conflicting elements of the system and functions of unknown x-element that is necessary for solving the problem. Then, this model of the problem is developed into a model of ARIZ ideal solutions as an ideal final result that contains the physical contradiction. Next, the model of the ARIZ ideal solution is reformed into the solutions for the initial problem with application of separation principles for physical contradictions, resources and scientific effects. All these actions are implemented in first five parts of the algorithm. Parts six-nine of ARIZ are devoted to reformulating the problem if there is no a good solution concept and to verifying the solving process for improvement of the obtained solutions.

Exploring problem situation. The process of problem solving starts from the interview with the customer and defining the problem statement. Typically, the situation that is described by the customer during the first interview has more than one problem – it is an important to define all these problems. Next, pick out the main problem that is the priority for the customer. The problem questionnaire provides valuable information that includes a detailed description of the problem situation and problem development background. We can also document previous attempts for solving this problem by the customer with a definition of the interactions and links between the technological operations or components of the system.

Formulating ARIZ model of a problem. The model consists of just two conflicting elements of the system: the product and tool. Define the technical contradiction between them and the function that should be provided by x-element for solving the problem. In order to develop this model, the first direct and second reversed technical contradictions are formulated. Select just one of the technical contradictions. This selection is based upon the main desired function in the contradiction. (Remember that a technical contradiction describes the conflict between parameters within a system: improvement of one parameter of the system leads to the worsening of another parameter.)

Developing ARIZ ideal solutions. In this stage, the technical contradiction should be replaced with a physical contradiction. A physical contradiction results from opposing requirements to a physical characteristic of a single parameter or element in the system. Successful formulation of a physical contradiction usually shows the problem's nucleus and the ways for resolving the problem. The step of formulating an ideal final result (IFR) helps to decide how to increase the beneficial factors and eliminate the harmful factors. Comparison of the developed solutions with the IFR demonstrates whether the solving process is true or false and not in the choice of the major contradictions. Thus, the ideal solution serves as an abstract model and a goal for future specific solutions.

Generating the specific solutions. During this stage, the ideal result should be transformed into specific solution concepts. Creation of solution concepts is implemented by applying listed resources, scientific phenomena and separation principles for resolving a physical contradiction. At this stage, the existing substance-field resources should be used together with other knowledge databases and tools of TRIZ for resolving the contradictions.

Subsequent evaluation of solution concepts and choosing the best one is the next stage that is implemented with the customer and includes a multi-factor evaluation of proposed new designs. The main criteria are usually adaptability for industry, cost of production and patentability. Also, TRIZ recommendations are used in this stage to make comparison one's solution concepts with the formulated ideal result and to make evaluation of the solutions with a cost-benefit-type of analysis.

| Robotic vacuum cleaners are modern high technology home appliances for the automatic cleaning of floors. At the present time, companies like Electrolux, iRobot and Samsung Electronics are carrying out research, developing projects and manufacturing these cleaners. One of the robot vacuum cleaners is the Samsung VC-RP30W shown in Figure 2. This vacuum can do many useful things. The robot detects the areas that need to be cleaned and cleans them. It works on different kinds of surfaces and has different settings for different floor types. This vacuum has safety sensors that detect stairs or other obstacles. The robot can do its job when home alone – it has a timer so it can be set to clean while you are away. The battery lasts about 50-60 minutes before needing to be recharged. If the battery gets low during operation, the robot vacuum automatically shuts down, returns to its charging base and recharges itself. When it is fully charged, it resumes vacuuming where it left off.

The simplified scheme and structure of a conventional robotic vacuum cleaner is shown in Figure 3. A robotic vacuum cleaner has driving wheels that are located at a lower portion of the cleaner body. Driving wheels are connected by a belt-drive. The upper portion of the cleaner body has an antenna for receiving and transmitting signals to and from a remote controller and distance sensors. The movement of a robot vacuum cleaner requires it to move in many different directions. (In this example, the description refers to the front and rear wheels of the robot vacuum cleaner – referring to its forward-moving orientation.) The interior of the cleaner body has a driving motor to generate a suction force, a contaminant collecting receptacle and a filter. The suction force is transmitted from the driving motor to a suction port, which is located at the lower portion of the cleaner body to draw in contaminants and dust from the cleaning surface and eventually into the receptacle. A robot vacuum cleaner works like an autonomous vehicle and draws in contaminants such as dust and dirt from a surface to be cleaned while automatically traveling in a specified area without being manually guided by a user. If a robot vacuum cleaner detects an obstacle such as furniture, appliances or a wall in the cleaning area with its distance sensor, the robot vacuum cleaner selects a right wheel motor and a left wheel motor to change its traveling direction and, therefore, does not crash into objects while it cleans. Problem: How to provide edge cleaning and preserve circle-shaped body In the next stage, formulate ARIZ model of the problem, start from the transformation of a problem situation to the formulation of the technical contradictions. Technical contradiction 1 is: "If the robot vacuum cleaner is circle-shaped, then the proven aesthetic design for the market is good but the coupling with walls and edge cleaning is bad." The scheme for this contradiction is shown in Figure 5 – the blue straight line indicates good interaction between elements and the wavy red line denotes the bad connection.

Technical contradiction 2 is formulated opposite to the first contradiction: "If the robot vacuum cleaner is non-circle-shaped (for instance, rectangle-shaped), then the coupling with walls and edge cleaning is better, but the proven aesthetic design for the market is bad." (See Figure 6.) From the two contradictions, we select the first, because this technical contradiction provides the preferred function for the market – the proven aesthetic design. Now we can see the conflicting pair, a circle-shaped robot and a wall. We cannot change the wall (our "product"), but we can modify the robot (our "tool").

In developing ARIZ ideal solutions, we start from the transformation of the selected technical contradiction to the physical contradiction. The formulation of the physical contradiction must be related to just one element of a cleaner: "The front body of the robot should be round for the aesthetic design for market and the robot body's front should have a flat surface to provide good coupling with the flat plane of a wall (or other obstacles) and for a good edge cleaning process." (See Figure 7.) Now we can formulate the ideal final result: "The robot's body surface, in the operating zone of interaction with the wall, itself provides flatness for plane connection between them, good edge cleaning and preserves a round-shaped body's surface for a good aesthetic market design with minimal modification of the body." Now it is time to transition to the next stage – generating the specific solutions. In order to approach the ideal solution we use any existing resources first. For solving the indicated contradiction, the principle of separation of contradictory requirements in time can be applied. A general model of the solution is the shape transforming from round to flat just in time of contact between the robot's body and the wall in the operating zone – by some force. |

| List of S-Field Resources | |||

| Resources | Substances | Fields | |

| Internal System | Product | Wall (or other obstacles) | Reactive force, rigidity |

| Tool | Robot's body | Driving force, friction force | |

| External System | Super-system | Suction air and port, exhaust air and port, battery, motor, wheels, sensors, control system, antenna, other robot components | Static and dynamic negative pressure, electricity, magnetic field, rolling friction, sliding friction, inertial force |

| Environment | Ambient air, floor, carpet, furniture, wall, obstacles | Atmospheric pressure, gravity force, geomagnetic field | |

| Byproduct | Exhaust air | Static and dynamic positive pressure | |

| One option is to use a "tip-up" self-moving bumper as shown in Figure 8, top view. The robot can move with the help of wheels and cleans surfaces with a vacuum suction port. When the robot approaches a wall, it sets its body front (or bumper) against the wall, as shown in Figure 9, side view. When it reaches the wall's surface, the bumper moves out of the way – there is a rotation of the bumper with a spring-bias joint around the robot body. Thus the suction port comes directly in contact with the wall surface, as shown in Figure 10, and better edge cleaning is achieved. When the robot moves off the wall, the bumper returns to its initial position by the restoring springs and the bumper's weight. The "free of charge" reaction force of the obstacle is applied only as a resource. As shown in Figure 8, the use of the rotating bumper satisfies both parts of the physical contradiction and approaches the ideal solution – the robot body is round, but changes to flat with minimal changes to the robot's design.

Problem: How to implement corner cleaning and to preserve circle-shaped body How can we clean carpets to the very corner? This is a new problem with a new set of contradictory requirements. The conventional design for solving this problem is connected with the application of a rectangular body shape or increasing the suction power. However, such solutions degrade vacuum cleaning time and do not satisfy the customer's requirement to preserve the existing circle-shaped body of the robot. We can formulate a new ARIZ model of a problem starting from new set of technical contradictions. Technical contradiction 1 is: "If the robot vacuum cleaner is circle-shaped, then there is a proven aesthetic design for market but the coupling with corner and corner cleaning are bad," as shown in Figure 11.

Technical contradiction 2 is: "If the robot vacuum cleaner is non-circle-shaped (for instance, rectangle-shaped), then coupling with the corner and corner cleaning is better, but the proven aesthetic design for market is bad," as shown in Figure 12. From two conflict schemes, we select the first again, because this technical contradiction provides the preferred function for the market – maintaining the proven aesthetic design. We now have a conflicting pair. (See Figure 11.) We cannot change the angle –our "product," but we can modify the robot, our "tool."

The next stage is developing the ARIZ ideal solution. We transform the first technical contradiction to the physical contradiction related just to one element of cleaner: "The front of the robot's body should be round for providing the aesthetic design for market and the body front should have a corner shape for good corner cleaning." (See Figure 13.) After developing the physical contradiction, we can formulate the ideal final result: "The robot's front surface, in the operating zone of interaction with the corner, itself provides the corner-shaped body good corner cleaning and preserves a round-shaped body's surface for a good aesthetic market design with minimal modification of the body." Now is a time to transition to the next stage – generating the specific solutions. By exploring the resources of our system, we can see that they are almost the same as the first problem except that the "product" is different. In this task, the corner is the new product, because it is with the corner that the robot's body (as a tool) interacts directly.

To implement this model, use the robot's body with a round and "elastic nose" as seen in Figure 14, side view. The robot's body has an elastic nose located at the front. When the robot approaches the corner area, it sets its elastic nose against the corner (see Figure 15, top view). Under reaction forces from the wall's corner, the elastic nose itself moves inside of the corner area (see Figure 16). The robot body with an elastic nose itself easily takes the shape of the corner and performs cleaning in this area.

Such a "soft nose" also allows the flat-edge cleaning process because a flat wall or other obstacles can deform the nose (see Figure 17). This interaction is acceptable with fragile and glass obstacles. It is especially important in domestic surroundings with expensive furnishings or in museums. To create the self-deforming nose, a foam or spongy polymer surface layer is used. The foam is an inexpensive and light material, easily deformed under a reaction force and can take on complicated shapes of obstacles' surfaces. We have resolved the physical contradiction with "soft nose" design that meets the requirements of the ideal solution. With the advantages of the previous design and with the newly perfected ability of adaptation to the complicated shape of obstacles, the robot still had some unexpected weak points. Domestic pets (cats and dogs) like to play with the vacuum cleaner and can easily damage their soft noses! After such abuse, the robot's capacity for work is degraded. The ideal final result in this case is: "the robot's body itself should provide the necessary flexible property of the front for good adaptation to complicated obstacles' shapes and solid properties for reliability and protection from pets." This result may be reached by the application of the principle separation of conflicting requirements in space. A physical model of the solution is for the front of the robot's body to have a solid surface for protection that also has flexibility and can be easily adapted to obstacle shapes by using substance-and-field resources.

Generating the specific solutions for technical implementation of this new physical model requires the front part to be made as shown in Figure 18. The outward layer of the front-part is comprised of separate solid plates that are connected with elastic plates on the inside layer. Such a front-part has, simultaneously, both rigid and pliable properties and can be formed to match different obstacles shapes under reaction forces as shown in Figures 19 and 20. The proposed design – with the adaptive front part of the robot's body – satisfies both parts of the formulated physical contradiction. The proposals are very close to the ideal solutions because the robot itself provides for resolving the indicated contradiction by using internal resources with minimal modification of the cleaner. |

Practical use of ARIZ allows you to create the strongest proposals for solving manufacturing and R&D projects. However, the mental work with the application of ARIZ demands more intellectual efforts and time in comparison to the use of the inventive principles or standards.

ARIZ will not solve your problem without your leading role – the algorithm is only a tool. It can assist, but cannot substitute for your own process of thinking. Altshuller said that, "ARIZ is just a tool for thinking, but it is not instead of thinking."

A constant narrowing of the problem area occurs during problem-solving with the ARIZ application. In the beginning, we are dealing with a whole system that is first transformed to a conflicting pair of technical contradictions and then changed to just one element. At that time, the initial problem situation is transformed – step-by-step – to a specific technical problem and then to a physical task. These transformations are carried out with the help of the basic algorithmic operators through formulations of the technical contradiction, physical contradiction and ideal final result. At the end of the solving process, all analysis is focused on the resolution of a detected final physical task. Finding this task and solving the problem on a physical level allows us to develop strong technical proposals. The operators (separation principles for physical contradictions, resources and scientific effects) are used for this purpose in the final stage.

Quiz. Which ARIZ tools (contradictions, ideal final result, resources, scientific phenomena) are used in the problem-solving processes described in the two following problems?

| Problem. When you work with a thin drilling bit that has diameter less then 1mm, you risk breaking it with the smallest effort or slip. Sometimes it is critical, because you can damage expensive work and there is no substitute for drilling bit. How can we protect the thin drilling bit against breakage during delicate work and prolong its lifetime? Solution. Spread bar soap on the surface of the drilling bit. The drilling bit will have a longer lifetime and will not break even under pressure from considerable side forces. |

| Problem. When we work with a soldering iron and want to solder many components, it is necessary to have a little more solder on the tip of the soldering iron. But the usual soldering iron cannot provide this feature and we have to interrupt the soldering process in order to place a new portion of tin on the tip's surface. Solution. Make a thin cut in tip. Due to this thin cut, the soldering tip can hold an increased quantity of solder. Therefore, the soldering process will go faster and you do not need to interrupt it as often to add on a new portion of solder. |

| Rope Problem Sometimes, we have to stretch a rope and tie knots in it in order to dry clothes. We should provide a good tension in the rope and have strong knots. Can we apply the ARIZ tools of contradictions and ideal solution to this problem? For instance, the rope itself will be tensioned and will have strong knots. How can we achieve this action without any complex devices and in a typical home environment? |

| Scissors Problem How can we sharpen a pair of scissors without a conventional sharpener and without the process requiring any special skills? The ideal solution can be stated like this: the scissors themselves will provide sharpening without a sharpener. Try to formulate contradictions, resolve them and correlate to the ideal solution using simple items that can be easily found in your home. |

| Shoes Problem Often during inclement weather our shoes get wet. Sometimes there is no option to change shoes although we really need dry shoes. How can we dry our wet shoes in just 10 minutes? Formulate the ideal final result for this problem: moisture itself will be removed from the shoes to provide dry shoes in 10 minutes, in normal home conditions and without any complexities. Formulate complete conflicts and then propose solutions to approach the ideal result. |

Val Kraev is the chief TRIZ officer of the Technical Innovation Center in Worcester, MA, USA, and has contributed several very valuable case studies to The TRIZ Journal. Contact Val Kraev at kraev (at) triz.org or visit http://www.triz.org.